Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Packaging: Wooden Box

Supply Ability: Monthly production capacity of 40~60 sets depends on the mold structure

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Packaging: Wooden box

Supply Ability: Export about 400-500 set moulds per year

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Our company has 16 years of rich experience in the field of mold making, focusing on the production of precision injection mould for bottle cap plastics, demonstrating extremely high professionalism and technical strength. Especially in the production of beverage Drinks Cap Mold, our company is proficient in the entire process from design to production, and can provide customers with high-quality and high-precision products.

Our company strictly controls the quality of mold production to ensure that each process meets high standards and requirements. This practice not only improves production efficiency, but also reduces the defect rate, thus ensuring the high-quality performance of the final product.

Having a strong and professional design team is a big advantage of our company. These designers not only have rich industry experience and deep professional knowledge, but also can provide personalized customized solutions according to the specific needs of customers, to ensure that the design of the mold meets the requirements of use, but also has aesthetic.

You also attach great importance to communication and cooperation with customers, and are committed to meeting their various needs. Whether it is product performance, price or delivery time, your company is able to provide competitive solutions, which has won wide praise from customers.

We also attach great importance to communication and cooperation with customers, and are committed to meeting the various needs of customers. Whether it is product performance, price or delivery time, your company can provide competitive solutions and win wide praise from customers.

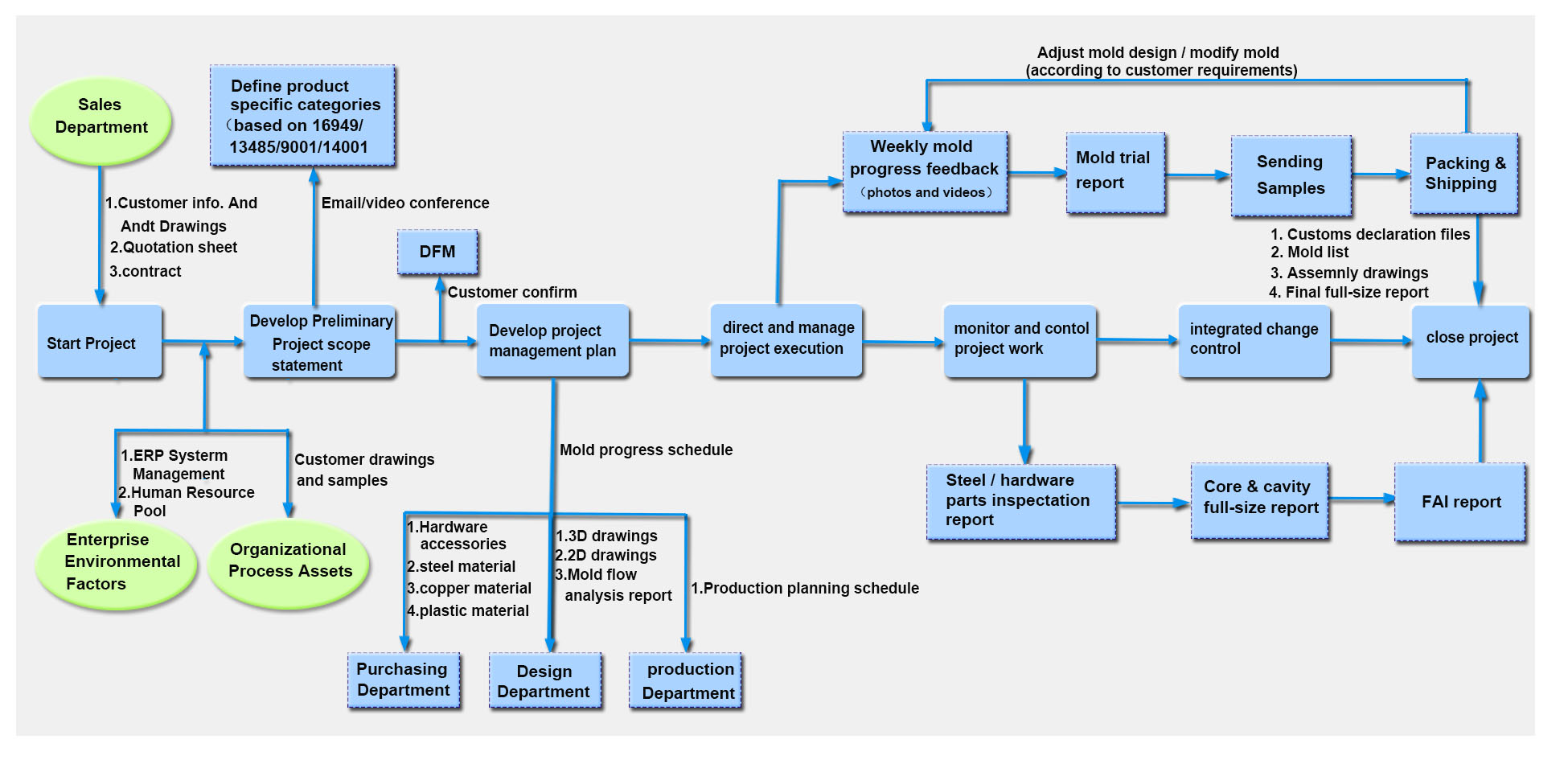

Production Flow Chart for Drinks Cap Mold

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.