Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Packaging: Wooden box

Supply Ability: Export about 400-500 set moulds per year

Cosmetic bottle cap mold customization and injection molding manufacturer.

Mold Design

Customization of cosmetic bottle cap mold starts with careful design. Our professional design team will use advanced CAD/CAM systems to conduct three-dimensional modeling based on customer needs and the specifications, shapes, materials and other characteristics of cosmetic bottle caps to ensure the accuracy and feasibility of mold design. During the mold design process, we will fully consider the process requirements of injection molding to ensure that the mold structure is reasonable and can produce high-quality cosmetic bottle caps efficiently and stably.

Collecting Materials

High-quality raw materials are the basis for ensuring the quality of cosmetic bottle caps. We purchase high-quality injection molding raw materials from reliable suppliers, such as ABS, PP, PE, etc., and select and match them according to the characteristics of different products. At the same time, we will also conduct strict quality testing on raw materials to ensure the qualification rate of raw materials and avoid product defects caused by raw material problems.

Injection Molding

Injection molding is the core link in Cosmetic bottle cap precision mould customization. We have advanced injection molding equipment and an experienced operating team, which can inject raw materials into the mold according to the requirements of the mold design, and form cosmetic bottle caps after cooling and solidification. During the injection molding process, we will strictly control parameters such as molding temperature, pressure, and speed to ensure that the bottle caps have accurate dimensions, smooth surfaces, and flawless surfaces.

Quality Inspection and Packaging

Before cosmetic bottle caps leave the factory, we will conduct strict quality inspections to ensure that the products comply with national and industry standards. We will also check the consistency and stability of the products to avoid quality problems. Products that pass the test will be cleaned and disinfected to ensure product hygiene and safety. Finally, we will pack according to customer's packaging requirements for transportation and storage.

Customized Services

We provide a full range of customization services, and customers can customize personalized cosmetic bottle cap injection mould and bottle cap products according to their own needs and preferences. Our design team will communicate closely with customers to understand their specific needs and provide professional suggestions and solutions. Whether it is the shape, color, material of the bottle cap, or the pattern, text, etc. on the bottle cap, we can customize it according to the customer's requirements to meet the customer's personalized needs.

After-Sales Service

We attach great importance to after-sales service and provide customers with a full range of technical support and solutions. If customers encounter any problems or need help during use, our professional team will respond promptly to provide technical support and solutions. At the same time, we will also regularly contact customers to understand product usage and feedback in order to continuously improve and enhance the quality of our products and services.

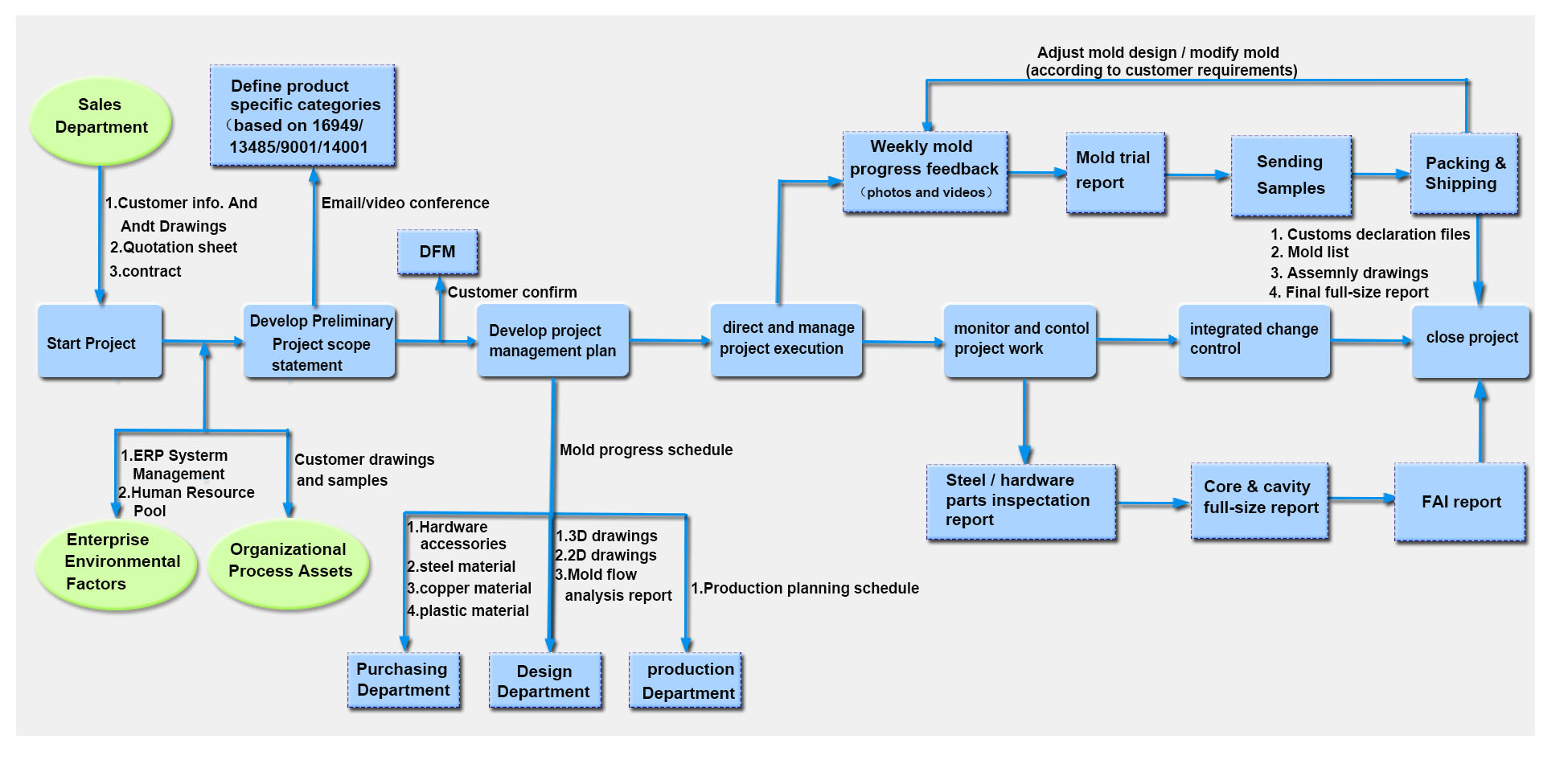

Production Flow Chart for Cosmetic Bottle Cap Mould

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.