Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Supply Ability: 500

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Packaging: Wooden Box

Supply Ability: Export around 400 to 500 sets of moulds per year

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year

Supply Ability: 500

Packaging: Wooden Box

Supply Ability: Export about 400-500 set moulds per year.

BMC communication equipment mold customization: manufacturing with superb technology and excellence.

Mold Design

In the customization process of BMC communication equipment molds, mold design is the first step. Our technical team relies on rich experience and professional technical knowledge to design mold solutions that not only meet product functional requirements but also adapt to the production process according to the customer's specific requirements and usage environment. Through accurate calculation and simulation analysis, the rationality, stability and reliability of the mold structure are ensured, laying a solid foundation for subsequent production.

Precision plastic molds Manufacturing

We use advanced manufacturing equipment and processes to ensure the accuracy and quality of mold making. From the selection of raw materials to the control of the processing process, we strictly follow industry standards and quality requirements. Through high-precision CNC machining, EDM machining and polishing processes, the dimensional accuracy, surface finish and fit accuracy of the mold are ensured, thereby improving the molding quality and production efficiency of BMC communication equipment.

Optimize Production Process

In addition to mold design and mold making, we are also committed to optimizing production processes and improving production efficiency. Through in-depth research and analysis of the production process, we find the key factors affecting production efficiency and product quality, and take effective measures to improve them. For example, optimizing the injection molding process parameters, improving the cooling efficiency of the mold, etc., thereby shortening the production cycle, reducing production costs, and improving the market competitiveness of the product.

Personalized Customization

We understand that each customer's needs are unique, so we provide a personalized, customized service. Whether it is the size, shape or special requirements of the mold, we can customize it according to the needs of our customers. Our technical team will communicate closely with customers to understand their specific needs and provide professional suggestions and solutions to ensure that the final product can meet customer expectations and requirements.

Quality Assurance and After-Sales Service

We know that quality is the lifeline of an enterprise, so we strictly control the quality of molds. Each mold will undergo strict quality inspection and testing before leaving the factory to ensure its stable performance, safety and reliability. In addition, we also provide comprehensive after-sales service to ensure that customers can get timely solutions when they encounter problems during use. Our professional team will provide customers with technical support and solutions to help customers better use and maintain molds.

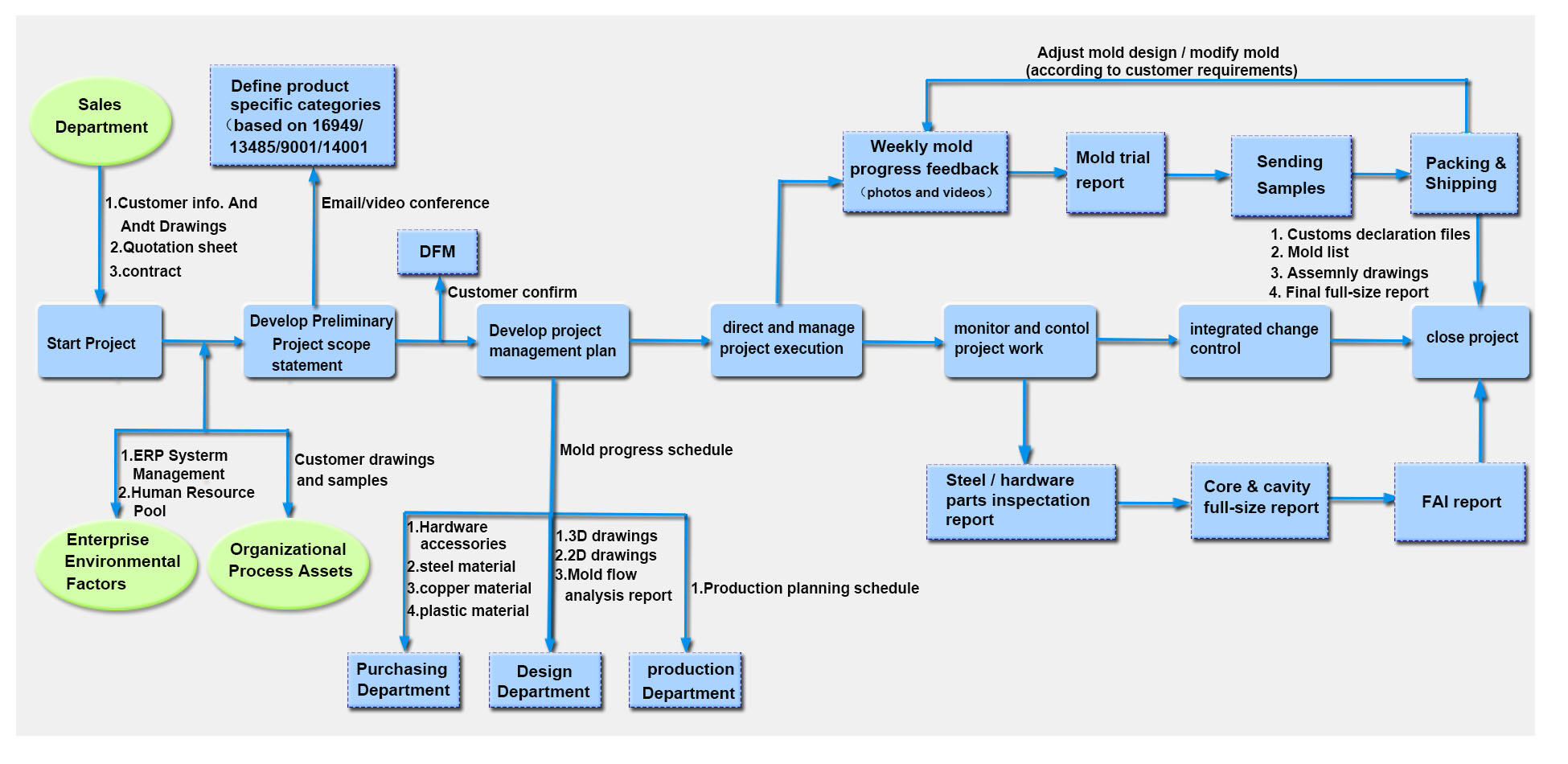

Production Flow Chart for BMC Communication Devices Mould

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.